Factory For Manual Bottle Liquid Filling Machine - Automatic Ultrasonic Tube Filler And Sealer HX-009 – HX Machine

Factory For Manual Bottle Liquid Filling Machine - Automatic Ultrasonic Tube Filler And Sealer HX-009 – HX Machine Detail:

Technical Parameters

| Model | HX-009 |

| Frequency | 20KHZ |

| Power | 2.6KW |

| Power Supply | AC220V/110V |

| Filling Range | A: 6-60ml B: 10-120ml

C:25-250ml D: 50-500ml ( could choose based on customer’s volume) |

| Filling Accuracy | ±1% |

| Capacity | 20-28pcs/min |

| Sealing Dia. | 13-50mm (Custom-made available) |

| Tube Height | 50-200mm |

| Air Pressure | 0.6-0.8Mpa |

| Air Consumption | 0.38m3/min |

| Dimension | L1630*W1300*H1580 |

| N.W | 425kgs |

Features:

* Machine could automatically finish tube feeding, registration mark identifying, filling, sealing with coding, end trimming, tube out feeding, fully automatic, save labor cost and lower production cost.

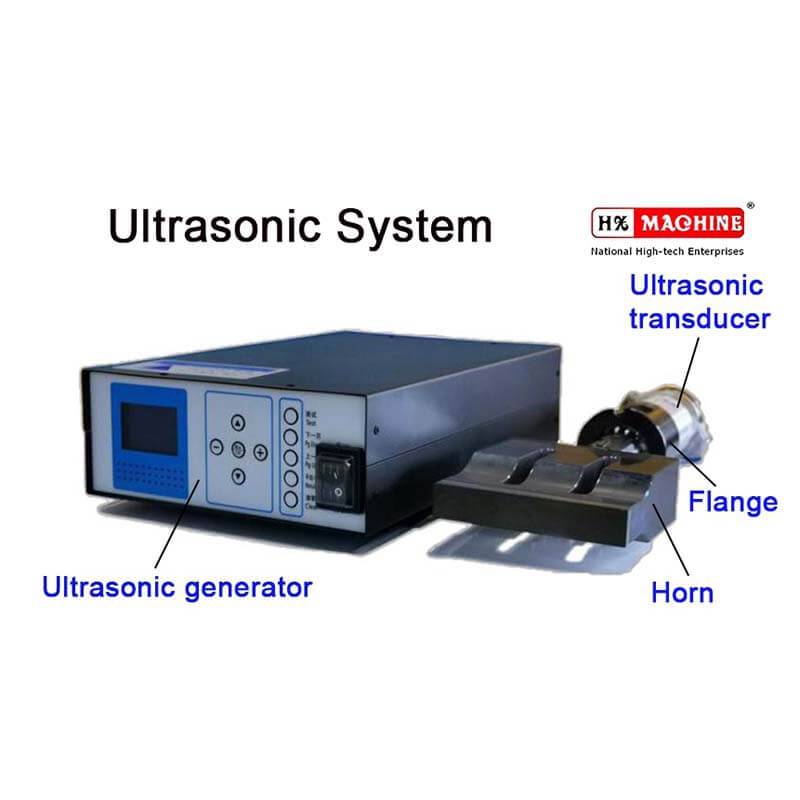

*Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

* Independent R&D for digital ultrasonic automatic tracking generator, no need manually adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

* PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen, could locate the problem and solve immediately.

* Machine is equipped with safety protection device and overload protection.

* Cam indexing system could position precisely for ten working stations.

* Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

* No tube, no fill, no tube, no seal function, reducing the tube material, machine and mould loss.

*Adopts Anti-dripping filling nozzle.

Application:

Widely used for food, Pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube filling and sealing.

Machine Options:

1. Auto Refill pump

2. Double jacket hopper with heating and stirring function

3. 316L Stainless Steel contact parts

4. Air blow design nozzle for high viscous and sticky material

5. Safety door with alarm and stop function

Product detail pictures:

Related Product Guide:

We stay with our company spirit of "Quality, Performance, Innovation and Integrity". We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Factory For Manual Bottle Liquid Filling Machine - Automatic Ultrasonic Tube Filler And Sealer HX-009 – HX Machine , The product will supply to all over the world, such as: Nepal, Ghana, Iran, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, allow us to work together to get success.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!