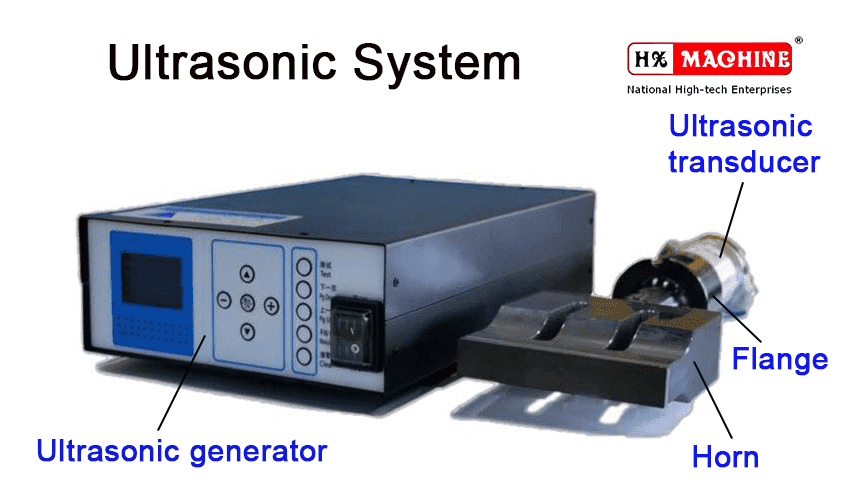

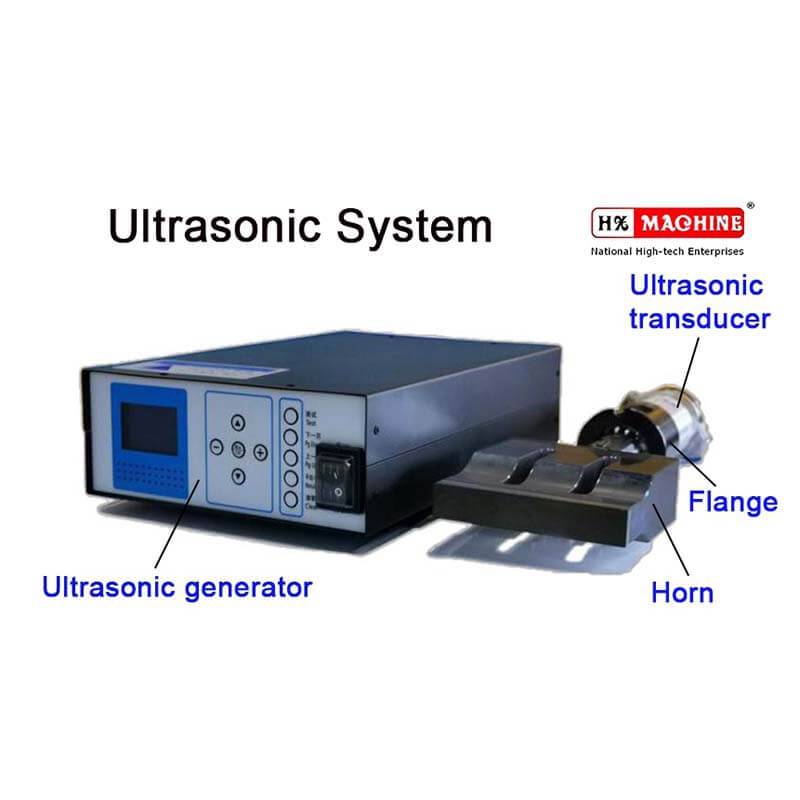

Excellent quality Ultrasonic Transducer Working - Whole set of ultrasonic system, including generator, transducer, horn and flange plate – HX Machine

Excellent quality Ultrasonic Transducer Working - Whole set of ultrasonic system, including generator, transducer, horn and flange plate – HX Machine Detail:

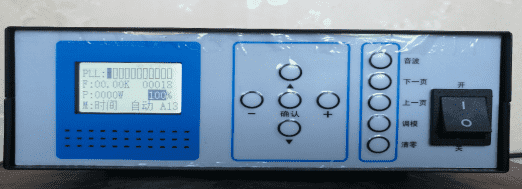

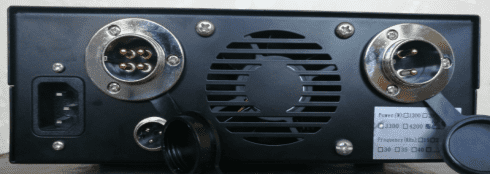

Ultrasonic Generator Technical Parameters

| Model | |

| Working frequency | 15KHz/20KHz |

| Working power supply | AC220V/110V 1PH 50/60Hz |

| Output power | 0-2600W |

| Output voltage | 0-3000V AC |

| Over-current protect current | 15A |

| Automatic frequency range | 1.2K |

| Automatic frequency tracking accuracy | 0.1Hz |

| Dimension | L 340*W 210*H 94mm |

| N.W | 4kgs |

Ultrasonic transducer:

Ultrasonic transducer is an industrial technique whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld.

Super performance, High conversion rate, Good heat resistance

Main Functions:

Low resonance impedance .high mechanical quality factor.

High electro-acoustic conversion efficiency and large amplitude.

lower heating, large temperature range; small performance drift, stable working.

Good material and long lifetime.

Mold (Horn):

Pros and cons of mold making is an important part of the ultrasonic, we introduce advanced blocking analyzer, mold spectrum analyzer, through precise testing for mold’s frequency and analysis of mold’s wave by these equipment, thus can help machine with more stable and effective output power of ultrasonic, and reduce the chronic damage because of incompatible frequency with machine, what’s more, prolong life for machine and mold.

* Horn size: 110x20mm 162x20mm 200x20mm 150x42mm (20K)

120x25mm 160x25mm 200x25mm 270x25mm 160x55mm (15K)

* Work mode: Continuous, intermittent

When working under continuous mode, please short cut the 2 and 3 pin. It is with safety protection and fault warning function.

* This ultrasonic system failure rate is low, consumables, durable, easy installation and debugging, maintenance is simple.

Application:

Core parts widely used in 3-ply mask, folding mask(N95), non-woven bags, plastic welding, tube closing production.

Instruction of use:

The frequencies of the ultrasonic transducer, booster and horn must be matched with each other.

The frequencies of horn and booster should be lower than the frequency of transducer.

The connection surface must ensure vertical and flatness, and the connection torque must be appropriate.

The Welding of electrode plate should be reliable and covered with damping glue.

The operating temperature of the ultrasonic transducer should be lower than 60 °C, and the input power should be lower than the rated power.

Product detail pictures:

Related Product Guide:

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for Excellent quality Ultrasonic Transducer Working - Whole set of ultrasonic system, including generator, transducer, horn and flange plate – HX Machine , The product will supply to all over the world, such as: Ecuador, Greece, Accra, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.