Top Quality Semi Automatic Tube Filling Sealing Machine - Semi-auto Ultrasonic Tube Filler And Sealer HX-006 – HX Machine

Top Quality Semi Automatic Tube Filling Sealing Machine - Semi-auto Ultrasonic Tube Filler And Sealer HX-006 – HX Machine Detail:

Technical Parameters

| Model | HX-006 |

| Frequency | 20kHz |

| Power | 2KW |

| Power Supply | AC220V/110V 1PH 50/60HZ |

| Filling Range | A: 6-60ml B: 10-120ml

C:25-250ml D: 50-500ml ( could choose based on customer’s volume) |

| Filling Accuracy | ±1% |

| Capacity | 18-30pcs/min |

| Sealing Dia. | 13-50mm |

| Tube Height | 50-200mm |

| Air Pressure | 0.6MPa |

| Air Consumption | 0.35m3/min |

| Dimension | L1300*W900*1550mm |

| N.W | 320kgs |

Features:

* Manually tube feeding, automatic registration mark identifying, filling, sealing with coding, end trimming, tube out feeding.

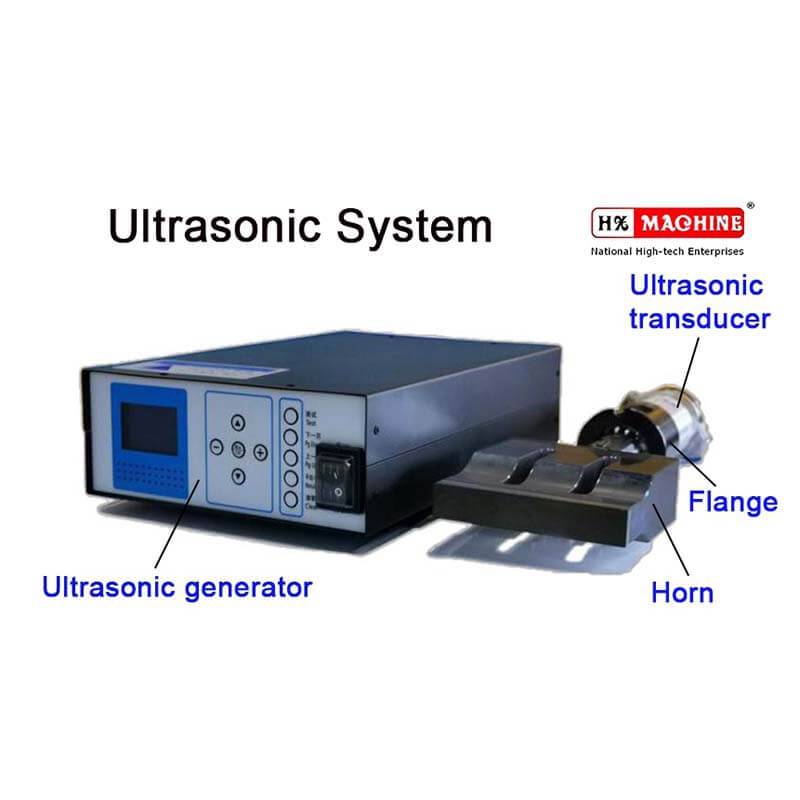

*Adopts ultrasonic sealing technology, no need warm-up time, more stable and neat sealing, no distortion, and low reject rate less than 1%.

* Independent R&D for digital ultrasonic automatic tracking generator, no need manually adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

* PLC with touch screen control system with alarm system could directly view the alarm information on the touch screen, could locate the problem, and solve immediately.

* Each station could be controlled independently in touch screen, friendly for adjustment between different tubes. Workers could use one tube only to set all the positions, saving much time and material.

* Cam indexing system could position precisely for ten working stations.

* Made of 304 stainless steel, acid and alkali resistance, corrosion resistance.

*No tube, no fill, no tube, no seal function, reducing the tube material, machine and mould loss.

*Adopts Anti-dripping filling nozzle.

Application:

Widely used for food, pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube filling and sealing.

Machine Options:

1. Auto-Refill pump

2. Double jacket hopper with heating and stirring function

3. 316L Stainless Steel contact parts

4. Air blow design nozzle for high viscous and sticky material

5. Frame with safety door could alarm and stop

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for Top Quality Semi Automatic Tube Filling Sealing Machine - Semi-auto Ultrasonic Tube Filler And Sealer HX-006 – HX Machine , The product will supply to all over the world, such as: Bangkok, Ireland, Swaziland, We always insist on the principle of "Quality and service are the life of the product". Till now, our products have been exported to more than 20 countries under our strict quality control and high level service.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.