2020 wholesale price Tube Sealer - Semi-auto Ultrasonic Tube Sealer HX-007 – HX Machine

2020 wholesale price Tube Sealer - Semi-auto Ultrasonic Tube Sealer HX-007 – HX Machine Detail:

Technical Parameters

| Model | HX-007 |

| Frequency | 20kHz |

| Power | 2kW |

| Power Supply | AC220V/110V 1PH 50/60HZ |

| Sealing Dia. | 13-50mm |

| Tube Height | 50-200mm |

| Capacity | 10-18pcs/min |

| Air Pressure | 0.5-0.6MPa |

| Dimension | L850*W600*H620mm |

| Packing dimension | L960*W710*H840mm |

| N.W/G.W | 75kgs/110kgs |

Features:

* Table top, practical and compact design, very convinient to work with customer exsiting filler for start-up manufacturers, market test, or laboratory sample proofing.

*Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

* Manually feed the tube, press start button, machine could automatically identify the registration mark, go into the sealing station, sealing (with coding), end trimming and go out for workers easy take out.

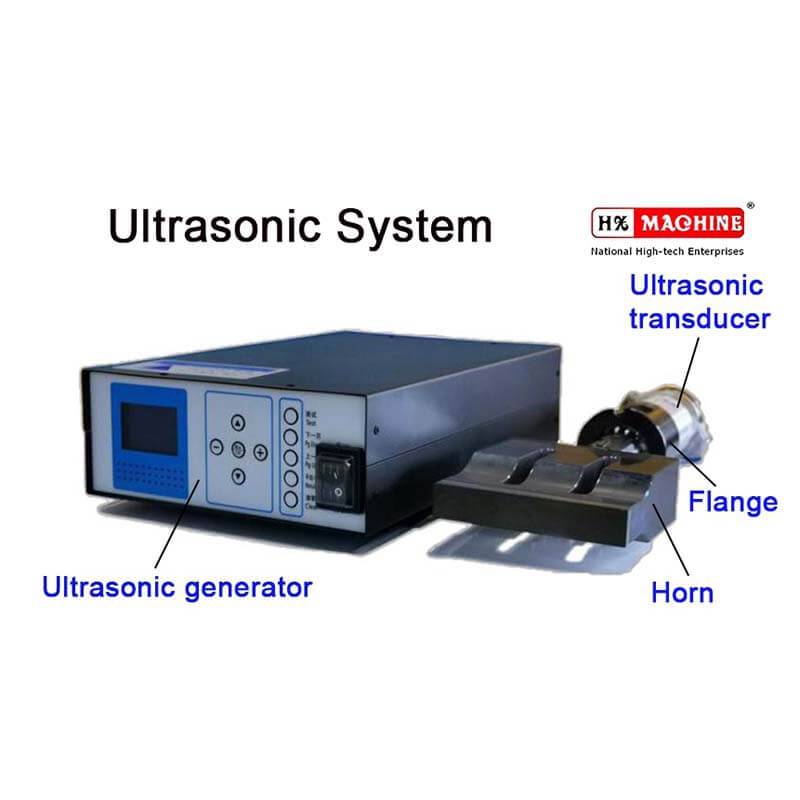

* Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

* PLC with touch screen control system, providing a friendly operation experience.

* Each action could be controlled independently in touch screen, friendly for adjustment between different tubes. Workers could use one tube only to set all the positions, saving much time and material.

* ”Panasonic” high sensitive sensor with a stepping motor, could track the registration mark precisely.

* Coding mould is slot position design, when replace the date coding, no need to readjust the balance.

* Quick adjustable lifting bracket by handwheel, could adjust based on different tube height.

* Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

*Safety Acrylic Cover, more safety and beautiful, anti-clamping hands.

Application:

Widely used for food, pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube sealing.

Machine Options:

1. Tube holders for different diameter

Product detail pictures:

Related Product Guide:

Together with the "Client-Oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for 2020 wholesale price Tube Sealer - Semi-auto Ultrasonic Tube Sealer HX-007 – HX Machine , The product will supply to all over the world, such as: United States, Grenada, South Africa, The quality of our merchandise is equal to OEM's quality, because our core parts are the same with OEM supplier. The above items have passed professional certification, and we not only can produce OEM-standard items but we also accept Customized Merchandise order.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.